Ansys, Inc. is a global public company based in Canonsburg. It develops and markets multiphysics engineering simulation software for product design, testing and operation. Ansys was founded in 1970 by John Swanson. In the 2000s, Ansys made numerous acquisitions of other engineering design companies, acquiring additional technology for fluid dynamics, electronics design, and other physics analysis.

Ansys analysis software is used to simulate computer models of fluid dynamics, structural mechanics, electromagnetics, multiphysics and system simulation as well as temperature fields for analyzing strength, toughness, elasticity, temperature distribution, electromagnetism, fluid flow, and other attributes. Ansys is used to determine how a product will function with different specifications, without building test products. For example, ansys software may simulate how a bridge will hold up after years of traffic, or how to design a slide that uses less material without sacrificing safety.

Most Ansys simulations are performed using the Ansys Workbench system, which is one of the main user interface. The interface that users interact with is a version of ANSYS Workbench called ANSYS Mechanical interface allows users to connect to geometry, build and modify their model, set up their solution, submit a solve, and review results. The solver is called ANSYS Mechanical APDL. This is the main ANSYS Multiphysics program.

Typically Ansys users break down larger structures into small components that are each modeled and tested individually. A user may start by defining the dimensions of an object, and then adding weight, pressure, temperature and other physical properties. Finally, the Ansys software simulates and analyzes movement, fatigue, fractures, fluid flow, temperature, heat transfer, distribution, electromagnetic efficiency and other effects over time.

When you press the solve button ANSYS Mechanical writes out commands in the languages used by ANSYS Mechanical APDL (ANSYS Parametric Design Language).

Here are some of my projects:

Ballistic Analysis

Armour-Piercing Fin-Stabilized Discarding Sabot / APFSDS Shell:

- Armour-piercing fin-stabilized discarding sabot (APFSDS), long dart penetrator, or simply dart ammunition, is a type of kinetic energy (KE) penetrator ammunition used to attack modern vehicle armour. As an armament for main battle tanks, it succeeds armour-piercing discarding sabot (APDS) ammunition, which is still used in small or medium caliber weapon systems.

Armour Penetration / APFSDS DM33 Shell:

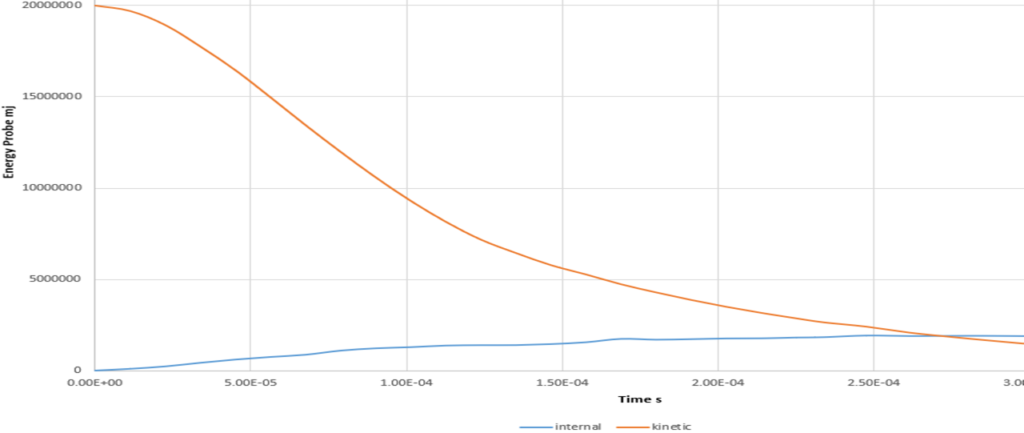

- In these analysis, 120mm RM: DM33 APFSDS ammunition were tested with front of the Leopard 2a4 armour. The armour design of Leopard 2a4 is a combination of RHA and ceramic materials with plates of different thickness. For these analysis, front armour was modelled with RHA material as single block, also in the analysis setting, material failure and damage criteria were defined for all used materials.

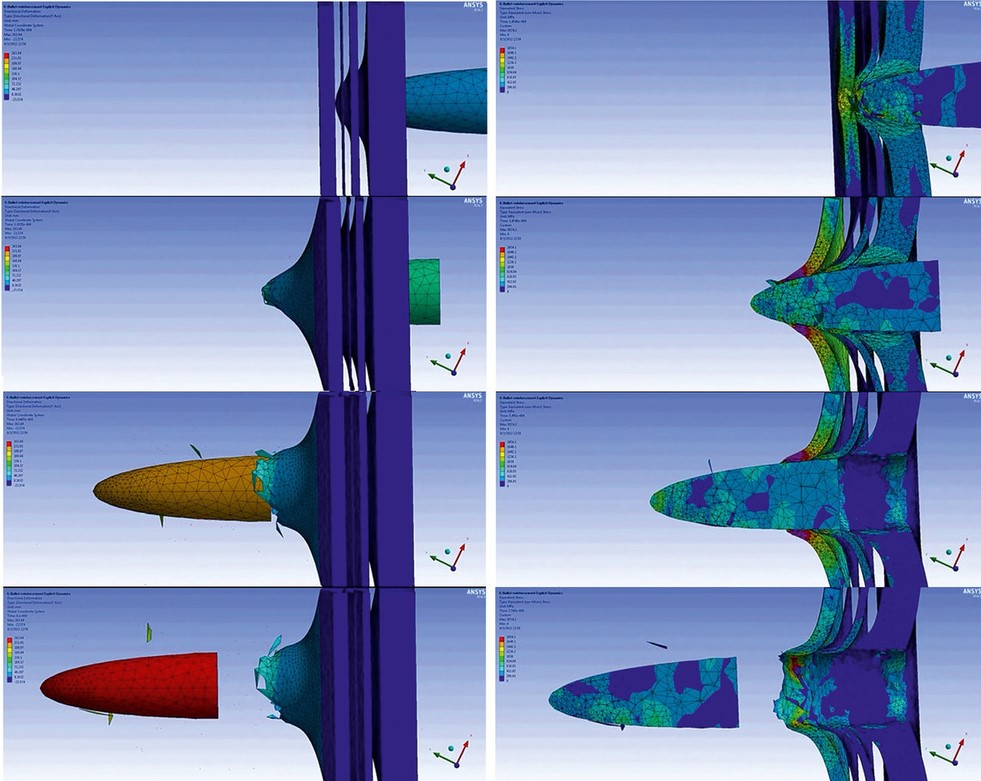

Armor-Piercing Shell / APHEBC Shell / Reinforced Concrete:

- The armour-piercing ballistic cap is a type of armor-piercing shell. Depends on thickness of armor, APHEBC, APHE, and APCBC shells can be used to penetrate concrete constructions such as shelter. In this analysis, APHEBC shell penetrated a reinforced concrete with 75 degree angle to target.

High Explosive Anti Tank / HEAT Shell / Shaped Charge:

- A high-explosive anti-tank (HEAT) warhead is a type of shaped charge explosive that uses the Munroe effect to penetrate thick tank armor. HEAT is a type of chemical energy (CE) penetrator ammunition used to attack modern vehicle armour. The warhead functions by having the explosive charge collapse a metal liner inside the warhead into a high-velocity superplastic jet. This superplastic jet is capable of penetrating armor steel to a depth of seven or more times the diameter of the charge but is usually used to immobilize or destroy tanks. In this analysis, Two different designed HEAT shell ammunitions, which were with 90 and 118 degree nozzle angle, were analysed to penetrate the same 300mm thick RHA (rolled homogeneous armour).

155mm M107 HE High Explosive Artillery Cartridge

- A high explosive shell is a type of chemical energy (CE) explosive and penetrator ammunition used to attack infantry and modern armoured light vehicle armour. In this analysis, 6.5 kg TNT exploded in the ammunition of 155mm M107. 80mm RHA (rolled homogeneous armour) failed to prevent penetration.

7.62x51mm AP / 308 AP Bullet:

- In these analysis, ballistic analysis is simulated. 7.62x51mm NATO (not black tip) / 308 caliber bullet hit RHA plate armor.

12.7x99mm AP / .50 cal BMG AP Bullet:

- In these analysis, ballistic analysis is simulated. 12.7x99mm NATO / .50 cal BMG AP bullet penetrated +100mm Aluminium.