In multibody analysis, contacts must be defined on geometries. With contact, boundary and load conditions, DOF (degree of freedom) on geometries need to be identified when we apply a structural analysis on parts, such as linear static, non-linear static, dynamics and so on.

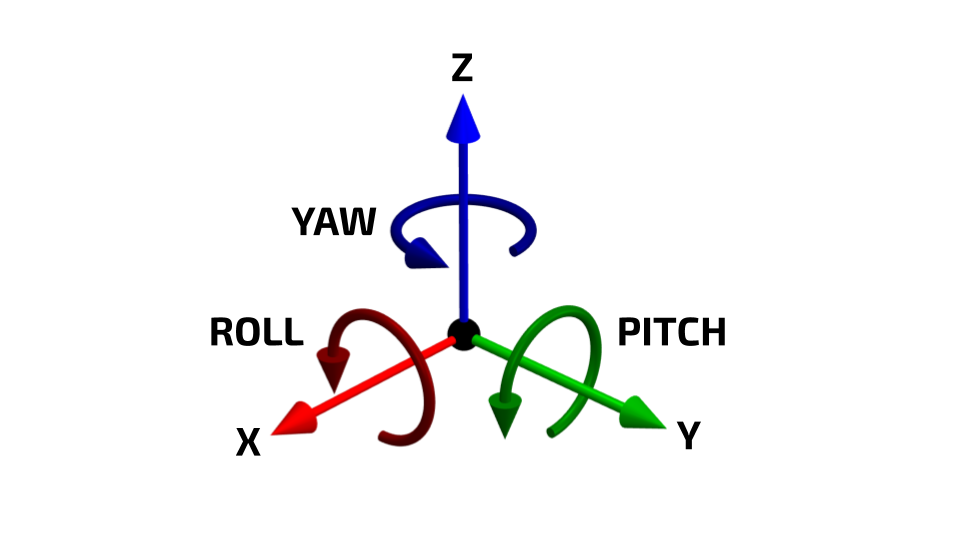

The DOF for a node represent the possible movement of the structure. Basically, a shell element has got 6 DOF that 3 translation and 3 rotation movement. DOF also represents which forces and moments are transferred from one element to the next. The results of a finite element analysis, (deflections and stresses), are usually given at the nodes.

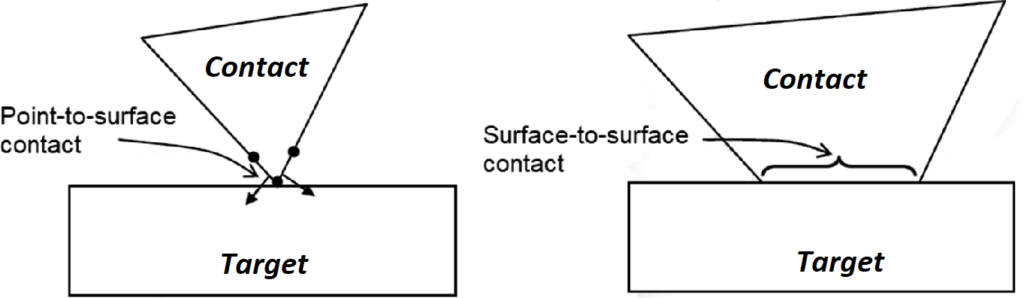

In structural analysis softwares, the contact is generated by pair. Three different contact behaviours are available. They are named node to node (point to point), node to surface (point to surface) and surface to surface. As default in Ansys software, point to surface and surface to surface contact types are used. For the point to surface contact, the “point” is contact and the “surface” is target.

For surface to surface contact, both contact and target are surfaces and they have to be determined which surface is contact and which is target. For the surface to surface contact, it is the first step to specify which is contact surface and which is target surface. Generally, convex surface is chosen as contact and concave as target. Besides, large surface is chosen as target when the size of one body in contact is very small compare to another one. Regardless of point to surface contact or surface to surface contact, they are identified as soon as expected.

Several contact types are used. These names might be called with different names according to softwares. In Ansys software, contact names are titled frictional, frictionless, rough, bonded and no separation.

Bonded Contact

In this contact, defined geometries act like one body. Bodies can not move (no slide and no separate) and rotate between each other.

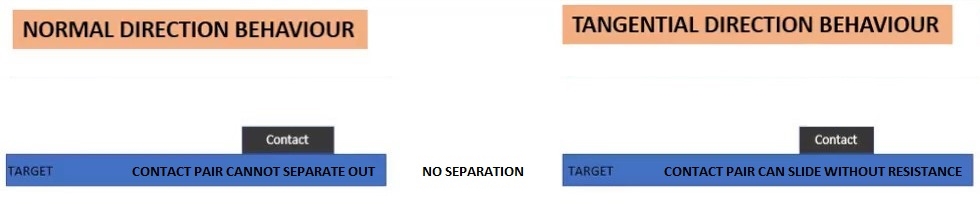

No Separation Contact

Once the contact is detected, then the target and contact surface are tied up for the rest of the analysis. Slide is possible, but the nodes in contact are bonded to the target surface in normal direction.

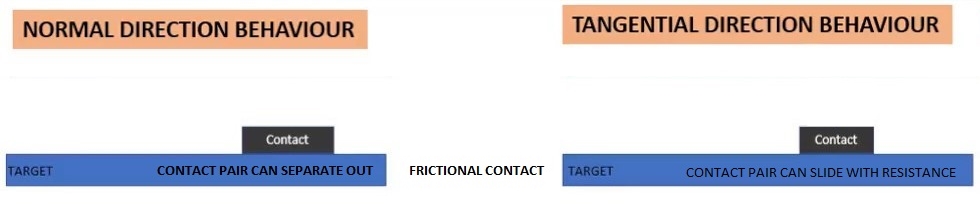

Frictional Contact

The contact pair can slide and separate on the target surface. Friction coefficients affect tangential movements.

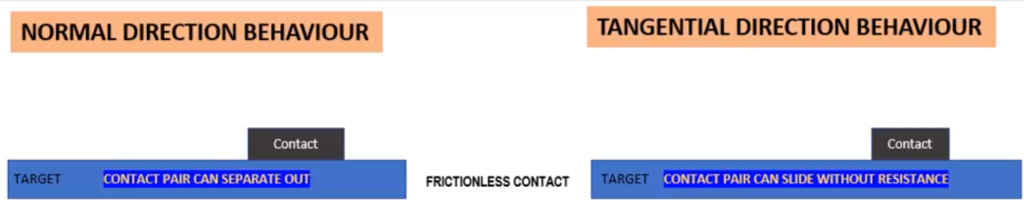

Frictionless Contact

The contact pair can slide on the target surface in the tangential direction and also can translate in the normal direction.

Rough Contact

Friction coefficient tends to be infinite on body. Contact pair can not move in the tangential direction because nodes in contact are glued on the target surface in tangential direction.