The emergence of computers and digital technologies is acknowledged the Third Industrial Revolution. Many of them are currently built on digital innovations and include elements such as automation, artificial intelligence (AI), biotechnology, internet of things (IoT) and 3D printing.

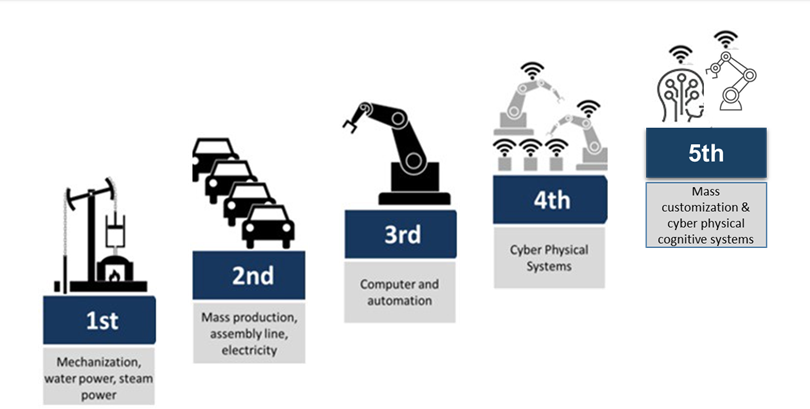

If we talk briefly about industrial revolutions, the first industrial revolution is the revolution in which steam-powered machines emerged. The second industrial revolution is the revolution of the steel industry, electricity, telegraph and internal combustion engines between 1870 and 1913. The third industrial revolution is the revolution in the computer, electronics and communication networks after the second world war. The fourth industrial revolution is the revolution in autonomous devices, 3D printers and robotic devices. The fifth industrial revolution is expected all over the world and it is being estimated that this revolution will be called the internet of things.

Computer aided manufacturing is another important part of the industrial revolutions. CAM has been being already actively used in manufacturing, construction and other sectors.

What is the CAM?

Computer aided manufacturing generally refers to use of numerical control (NC) computer software applications to create detailed instructions (G-code) that operate computer numerical control (CNC) machine tools for manufacturing parts. Manufacturers in various industries rely on CAM’s ability to produce high quality parts.

A broader and simpler definition is this: any production process that uses computer software to facilitate, assist, or automate parts of the production process.

How does CAM work?

Computer aided manufacturing is mostly used software to convert drawings and data into detailed instructions that can run some kind of automated tool. For instance, a 2D digital drawing can be used to guide a laser or physical cutting tool to cut the coating or other components to suit an architect’s design. The programming language is produced from the drawing or other dataset that is operated to control the machine tool is called G Code within the industry. This G code controls all the movements on the CNC by telling the servo motors where to move, how fast it will move, and which path to follow. To sum up, G code is a programing language that CNC machines can understand.

Author: Mehmet ASLANHAN